Tailored Excellence in Sheet Metal Fabrication

No MOQ Limited, Factory Direct, Lead Time As Fast As 2 Days - Unleash the Power of Customized Sheet Metal Solutions! Elevate Your Precision Manufacturing Experience with Our Exceptional Services!

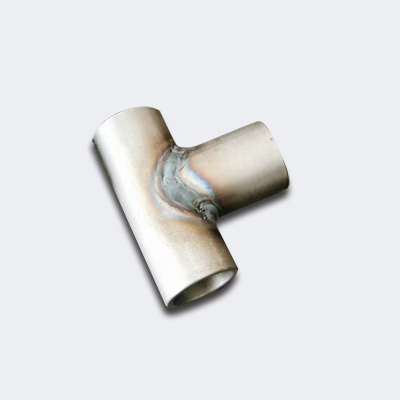

TurnkeyModel owns 15 sets of laser welding equipment, includes: Fiber laser welding machine: uses fiber laser source for high-precision welding, suitable for fine connections of various metal materials. Laser spot welding machine: Achieve small-area, high-aspect-ratio spot welding of components and improve welding accuracy. Semiconductor laser welding machine: Using semiconductor lasers for welding, it is suitable for efficient welding of conductive materials. CO2 laser welding machine: uses CO2 laser source for welding, suitable for different types of metal materials. Pulse laser welding machine: Fast and precise welding of materials is achieved through pulse laser technology. Galvanometer laser welding machine: Use the galvanometer system for laser welding to improve welding speed and efficiency. Laser welding technology is mainly used in sheet metal processing in automobile manufacturing, hardware products, aerospace, medical equipment and other fields. Sheet metal laser welding processing technology has the advantages of high precision, high efficiency, high quality, etc., and is widely used in many fields.

Place the part to be welded into the fixture and adjust the welding parameters. (such as laser power, welding speed, etc.)

Fix the part in the appropriate position to ensure that it does not move during the welding process

Start the laser welding equipment and weld according to the pre-set parameters

After completing welding, perform quality inspection on the part

Clean off welding slag and other impurities on the surface of the part, and perform surface treatmetn as needed, such as polishing

Record the data during the welding process and archive it for safekeeping

Call Us:

Email Us:

Opening Hours:

Copyright © 2025 Shenzhen Tengqi Technology Co., Ltd All Rights Reserved